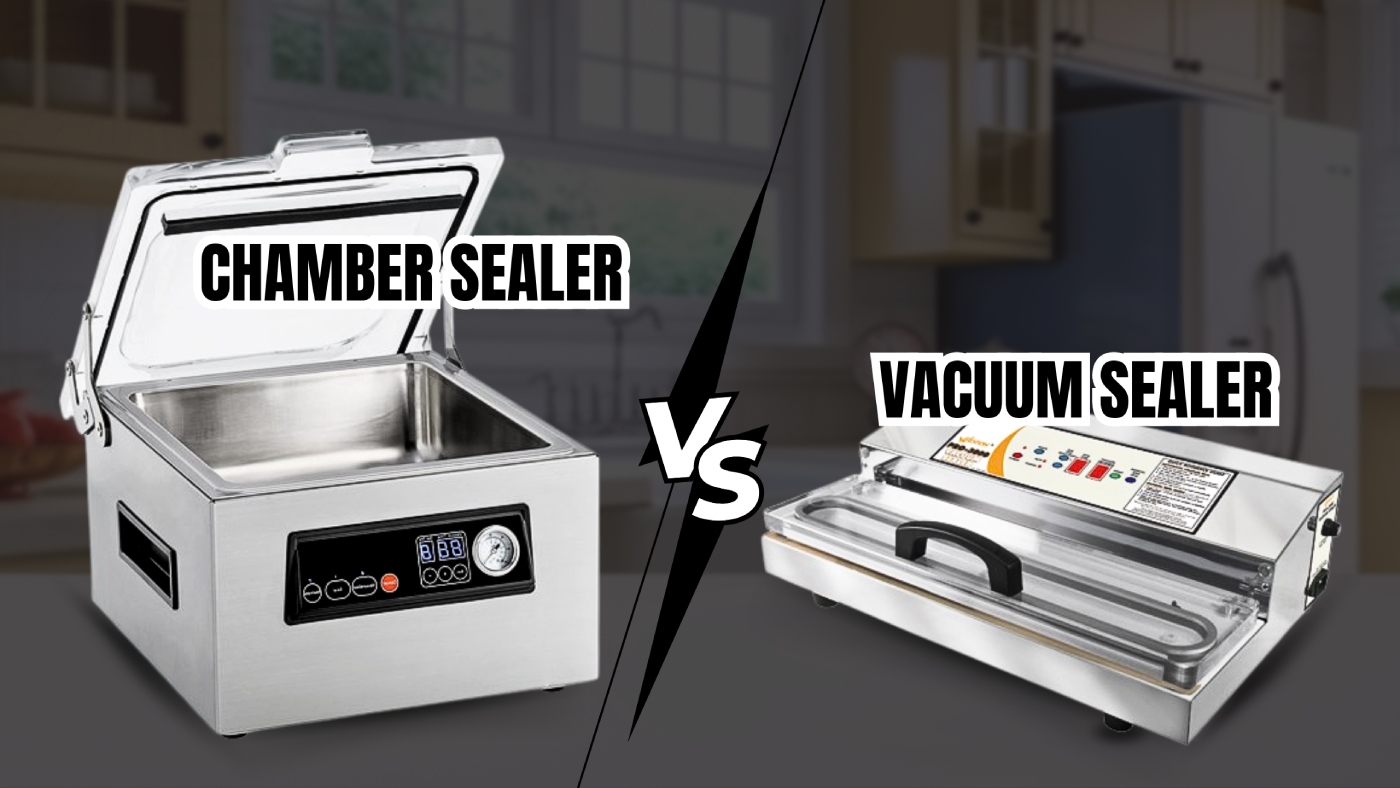

Chamber Sealer Vs Vacuum Sealer: Preservation Pros

When comparing chamber sealers and vacuum sealers, you’ll find chamber sealers excel in sealing liquids and moist items without spills. They operate by removing air from both the bag and the chamber, ensuring a tighter seal.

Chamber sealers can handle larger quantities and various bag types, making them ideal for frequent use or commercial applications. While they tend to be more expensive, their efficiency and versatility can justify the investment.

On the other hand, traditional vacuum sealers struggle with liquids and may require specialized bags. Understanding these differences can help you make an informed choice for your sealing needs.

- Ensures Leak-Free Sealing – Keep your liquid-rich foods fresh for longer with the Avid Armor food…

- Marinating Made Easy – Unlike regular vacuum sealers for food, our kitchen sealing machine lets you…

- Easy-to-Use Food Packing Machine – This vacuum seal machine has straightforward, one-touch controls…

- Dollar Saver: Preserve food up to 3 years in the freezer, maintaining its freshness and taste

- Bag Optimization: Minimizes bag waste with a built-in roll cutter for custom-sized bags

- Consistent Sealing: Dual heat sealing strips ensure optimal vacuum level and an airtight seal

Key Takeaways

- Chamber sealers remove air from the entire chamber, while vacuum sealers only extract air from the bag, affecting sealing efficiency.

- Chamber sealers can handle liquids and moist products effectively, whereas traditional vacuum sealers struggle with such items.

- Chamber sealers are typically larger, more expensive, and suited for commercial use, while vacuum sealers are more compact and budget-friendly for home users.

- Sealing times are faster with chamber sealers due to double sealing options, ensuring consistent and wrinkle-free seals.

- Chamber sealers can seal a variety of bag types and larger quantities, providing versatility for different applications compared to vacuum sealers.

Key Differences

When comparing chamber sealers and vacuum sealers, several key differences stand out that can greatly impact your sealing experience.

First, chamber sealers excel in sealing liquids without spills, thanks to their ability to remove air from the entire chamber, not just the bag. This guarantees an even pressure inside and outside the bag, preventing any movement of liquids during the sealing process.

In terms of functionality, chamber sealers can handle larger quantities of food and various bag types without needing specialized mesh bags. They’re particularly beneficial for applications like lacto-fermentation and marinating, where an oxygen-free environment and efficient use of marinade are vital. Additionally, chamber sealers can effectively use regular and full mesh vacuum sealer bags, offering more versatility in bag selection.

Cost and size also play a significant role; chamber sealers are generally pricier and larger, making them more suited for commercial use, though smaller models exist for home use.

Their oil-lubricated pumps provide better durability and vacuum drawers, but they require more maintenance.

Performance-wise, chamber sealers offer faster sealing times and a double sealing option for thicker bags, guaranteeing a robust, airtight seal that minimizes freezer burn.

These features make chamber sealers a versatile choice for serious food preservation.

Working Principles

Understanding the working principles of chamber sealers and vacuum sealers is crucial for maximizing their effectiveness in food preservation.

Chamber sealers operate within a vacuum chamber, where air is removed from both the chamber and the bag simultaneously. The vacuum pump extracts air, creating a low-pressure environment, while a heated sealing bar melts the bag’s opening to create an airtight seal. This process guarantees no air can re-enter, preserving the contents effectively. Additionally, this method significantly extends shelf life by inhibiting the growth of bacteria and fungi, thus maintaining food quality.

On the other hand, vacuum sealers utilize a different approach. They consist of a lid assembly, vacuum pump, and sealing strip. When you place the bag into the sealer, the pump generates suction to remove oxygen, leading to food spoilage. The sealing strip heats and fuses the bag’s edges, forming a secure seal.

While both methods aim to eliminate air, chamber sealers excel in sealing liquids and delicate items due to their controlled environment.

In contrast, vacuum sealers rely on the bag itself to form the vacuum chamber.

Benefits and Advantages

When you use a chamber or vacuum sealer, you greatly extend the shelf life of your food products by effectively removing air and preventing bacterial growth. This quality preservation not only maintains the freshness of your items but also enhances their overall appearance and safety. Additionally, vacuum-sealed food can last 3-5 times longer than non-sealed items, making it a valuable investment for both home and commercial kitchens.

Shelf Life Extension

A notable advantage of vacuum sealing is its remarkable ability to extend the shelf life of various foods, often increasing storage time by three to five times compared to traditional methods.

This extension comes from several key benefits:

- Increased Storage Time: Foods like vacuum-sealed beef can last up to 2-3 years in the freezer, compared to just 6 months when wrapped conventionally.

- Reduced Bacterial Growth: By removing air, vacuum sealing considerably limits the growth of bacteria, molds, and yeast, enhancing food safety. This is particularly important as certain foods require special precautions due to risks associated with gas production and mold growth.

- Oxidation Minimization: Vacuum sealing slows down oxidation, which is responsible for food degradation, ensuring your items stay fresher longer.

- Improved Freshness: It locks out contaminants while locking in moisture, preserving the original quality of your food.

Quality Preservation

Maximizing quality preservation is one of the standout benefits of using chamber sealers and vacuum sealers. These devices effectively maintain the integrity of your food by preventing oxidation, which preserves flavor and nutrients.

In addition, the moisture control offered by chamber sealers keeps food from drying out, ensuring a fresh taste every time you open the package. Furthermore, reliable sealing is crucial for food preservation, as it significantly enhances the longevity of your stored items.

Here’s a quick comparison of the preservation capabilities:

| Feature | Chamber Sealer |

|---|---|

| Preserves Flavor | Yes, prevents oxidation |

| Nutrient Preservation | Yes, halts oxidation processes |

| Moisture Control | Yes, prevents drying |

| Freezer Burn Prevention | Yes, removes air |

| Liquid Sealing | Yes, effective for liquids |

The airtight seals created by vacuum sealing prevent not just moisture and air exposure, but also unpleasant odors. Additionally, vacuum sealing allows for better marination, enhancing flavors considerably. When it comes to quality preservation, both chamber and vacuum sealers provide an efficient and convenient solution to keep your food fresh and flavorful for longer periods.

Choosing the Right Sealer

Choosing the right sealer hinges on your specific needs and usage patterns.

It’s crucial to evaluate several factors before making a decision. Here are four key points to assess:

- Volume of Use: If you’re sealing frequently or in large quantities, a chamber sealer is ideal.

- Variety of Foods: Chamber sealers excel in handling both solid and liquid foods, while external sealers are better for dry goods. Additionally, chamber sealers are preferred for marinating foods effectively due to their ability to handle liquids.

- Space Constraints: For home users with limited space, external sealers offer a compact solution.

- Maintenance: Chamber sealers allow for quick changes to the seal bar, minimizing downtime for maintenance.

Commercial and Industrial Use

Utilizing chamber sealers in commercial and industrial settings greatly enhances efficiency and product preservation. These machines operate by creating a vacuum in a sealed chamber, allowing for higher vacuum levels compared to external sealers. This precision is essential for products requiring specific conditions, such as meats and cheeses in the food industry, where spoilage needs to be minimized.

Chamber sealers excel in handling liquid and sensitive products without damaging them, making them ideal for various applications. In electronics, they protect components from moisture and dust, ensuring integrity. For medical products, maintaining sterility is paramount, and chamber sealers play an important role in this process, especially in ensuring high vacuum levels for effective sterilization.

The versatility of chamber sealers extends to dry goods, preserving grains and protein powders effectively by minimizing air exposure. With operational advantages like processing multiple bags per cycle and providing consistent, wrinkle-free seals, these machines are user-friendly and efficient. They often include features like gas flush options for precise atmosphere control.

Maintenance and Care

To guarantee your vacuum sealer operates efficiently, you need to implement regular cleaning procedures and inspect sealing components frequently. Proper storage guidelines also play an essential role in maintaining the machine’s integrity and longevity. Additionally, ensure that you regularly check the decompression and filtration components to prevent potential issues during operation.

Regular Cleaning Procedures

Maintaining the performance of your chamber or vacuum sealer hinges on regular cleaning procedures that keep both the exterior and internal components in peak condition.

By adhering to a systematic cleaning routine, you’ll enhance the lifespan and efficiency of your machine. Here are some essential cleaning tasks you should prioritize:

- Exterior Wipe: Use a damp cloth with mild detergent to clean the exterior, removing dust and grime.

- Chamber Cleaning: After each use, clean the vacuum chamber and seal the bar with a soft cloth or sponge to eliminate food residues.

- Internal Components: Regularly clean the vacuum pump and motor to guarantee smooth operation, and lubricate sliding parts every 2-3 months. Additionally, inspect the sealing channel for food particles or liquid spills to ensure optimal sealing performance.

- Thorough Drying: Always dry the machine completely post-cleaning to prevent mold or mildew growth.

Remember to unplug the machine before cleaning for safety, and avoid abrasive cleaners to protect surfaces.

Inspecting Sealing Components

Regular inspection of sealing components is essential for guaranteeing peak performance and longevity of your sealer. Start by checking the sealing bar for any damage after each use. If the seal quality diminishes, replace the seal tape promptly. Inspect the seal wire for deformation; damaged wires necessitate replacing the entire seal bar. Remember to clean the seal bar with a damp cloth only.

Next, monitor the oil levels through the sight glass every couple of weeks. Top up the oil as needed to prevent pump damage, and run the oil conditioning program monthly if your model supports it. Address any oil leaks immediately, and regularly lubricate sliding parts and switch blocks. Regular oil checks help prevent contamination from affecting performance.

Pay attention to the vacuum pump’s performance. Listen for unusual noises like chattering or hissing, and check for consistent performance. Conduct test cycles to assess pump speed and vacuum efficiency, noting any operational changes.

Finally, the chamber and filter are inspected after each use. Clean the chamber with a damp cloth and mild soap, guaranteeing no debris remains. Check the filter for blockages and ensure the filter cup is free of water to maintain peak functionality.

Storage Guidelines and Tips

Effective storage of vacuum-sealed items guarantees their longevity and quality, making it essential to follow specific guidelines. Here are some key tips to achieve peak preservation:

- Cool Before Sealing: Always allow food to cool to room temperature before sealing. This prevents moisture buildup that can lead to freezer burn and bacterial growth.

- Choose the Right Bags: Use bags that are compatible with your vacuum sealer type. Chamber sealers require smooth bags, while external sealers work best with textured bags. Having various sizes on hand helps accommodate different food types.

- Organize Properly: Flatten vacuum-sealed bags to save space and enhance storage efficiency. Store bags in a manner that prevents damage to seals, as this maintains freshness and extends shelf life. Proper organization also helps in identifying items quickly, reducing the time bags are left open during retrieval.

- Adjust Sealing Techniques: Tailor your sealing methods based on the food type. For liquids and delicate items, use a chamber sealer, while external sealers are ideal for dry goods.

Always wipe the bag’s top section to achieve a strong seal.

Customer Reviews and Experiences

Reading through customer reviews reveals a wealth of insights into the performance and reliability of chamber sealers. Many users praise these devices for their ability to seal liquids without any spillage, making them ideal for soups, sauces, and marinades. For instance, the VacVida VS301 and Anova Pro stand out for their effectiveness at sealing moist products, which is a common concern with traditional vacuum sealers.

In terms of overall performance, models like the VacMaster VP112 receive accolades for their durable construction and adjustable settings, providing users with control over sealing pressure and time. Customers appreciate the versatility of chamber sealers, noting their ability to handle a wide range of products, including electronics and medical supplies. This versatility is attributed to the fact that chamber vacuum sealers can effectively seal liquid products, making them suitable for various applications.

Durability and maintenance are also highlighted, with users reporting long-lasting performance and minimal issues. The VacVida VS301, while requiring occasional oiling, remains easy to maintain.

Customer service experiences are largely positive, particularly with the VacMaster VP112 and VacVida VS301, where users commend prompt support and reliability. Overall, satisfaction remains high, showcasing chamber sealers as a dependable choice for various sealing needs.

Frequently Asked Questions

Can Chamber Sealers Accommodate Different Bag Sizes?

Yes, chamber sealers can accommodate different bag sizes.

For instance, the Anova model fits bags up to 11″ wide, while larger machines like the JVR Vac110 handle bags up to 11″ x 16″.

You can also customize bag sizes by sealing and trimming to match your machine’s specifications.

With various thickness options available, you’ve got flexibility for different food types and storage needs, ensuring you can find the right fit for your requirements.

How Long Does a Typical Sealing Process Take?

A typical sealing process takes around 35-50 seconds, depending on your specific settings for items like meat, liquids, or dry food.

The sealing time is consistent across different bag types since it’s based on the machine’s capabilities. For most bags, you’ll find that 2-3 seconds is sufficient, but this can vary with custom or thicker materials.

Remember to add an extra second for cooling to guarantee a secure seal.

Are Chamber Sealers Noisy During Operation?

You might imagine a chamber sealer roaring like a jet engine, but it’s actually much quieter.

During operation, chamber sealers typically hum around 65 dB, similar to a regular conversation. In contrast, other types can blast noise levels up to 95 dB, akin to a vacuum cleaner.

This design minimizes vibrations and distributes pressure evenly, creating a more serene kitchen experience.

You’ll appreciate the quieter atmosphere, especially during late-night cooking sessions.

What Safety Features Should I Look For?

When selecting a sealing device, look for features like consistent vacuum levels that guarantee uniform preservation and prevent spoilage.

Check for contamination prevention measures, such as easy cleaning options and safe storage recommendations.

Confirm it can handle various materials, including liquids, without leakage.

Familiarize yourself with operational guidelines to maintain safety during use, and inspect seals regularly to avoid bacterial growth in stored foods.

These features collectively enhance your sealing experience.

Can I Use My Vacuum Sealer for Sous Vide Cooking?

Yes, you can use your vacuum sealer for sous vide cooking. It effectively removes air from bags, preventing oxidation and spoilage.

Make sure you use compatible, heat-safe bags that can withstand the cooking temperature. Seal your ingredients tightly, submerge them in a water bath, and maintain a consistent temperature for even cooking.

Your Perfect Sealer Awaits: Choose Wisely

In summary, whether you choose a chamber sealer or a vacuum sealer largely hinges on your specific needs. Coincidentally, both options excel in preserving food, but their applications differ greatly.

If you’re sealing larger quantities or liquids, a chamber sealer might just be the perfect fit. However, for everyday use and smaller items, a vacuum sealer could be ideal.

Ultimately, understanding these nuances will guarantee you make an informed decision that aligns with your sealing requirements.

- Infuse/Extract: In a pressurized environment, the distinct flavors from aromatic foods or herbs can…

- Compress/Pickle: This setting uses pressure within the chamber to compress certain fruits and…

- Dry/Cool: Use this program to boil water off of products in the chamber, like a freshly baked loaf…

- KEEP FOOD FRESHER & SAVE MONEY: The POTANE VS2690 vacuum sealers use enhanced heating wires and…

- 8-In-1 EASY PRESETS&SMART CONTROL SYSTEM: 4 operation modes and four vacuum sealing modes. It can…

- SLOPING TOP DESIGN: The sloping top design prevents the juice from being drawn out while vacuuming…

Last update on 2026-03-02 / Affiliate links / Images from Amazon Product Advertising API